Billet Intake Manifold - Alcohol

Better Performance. Safer.

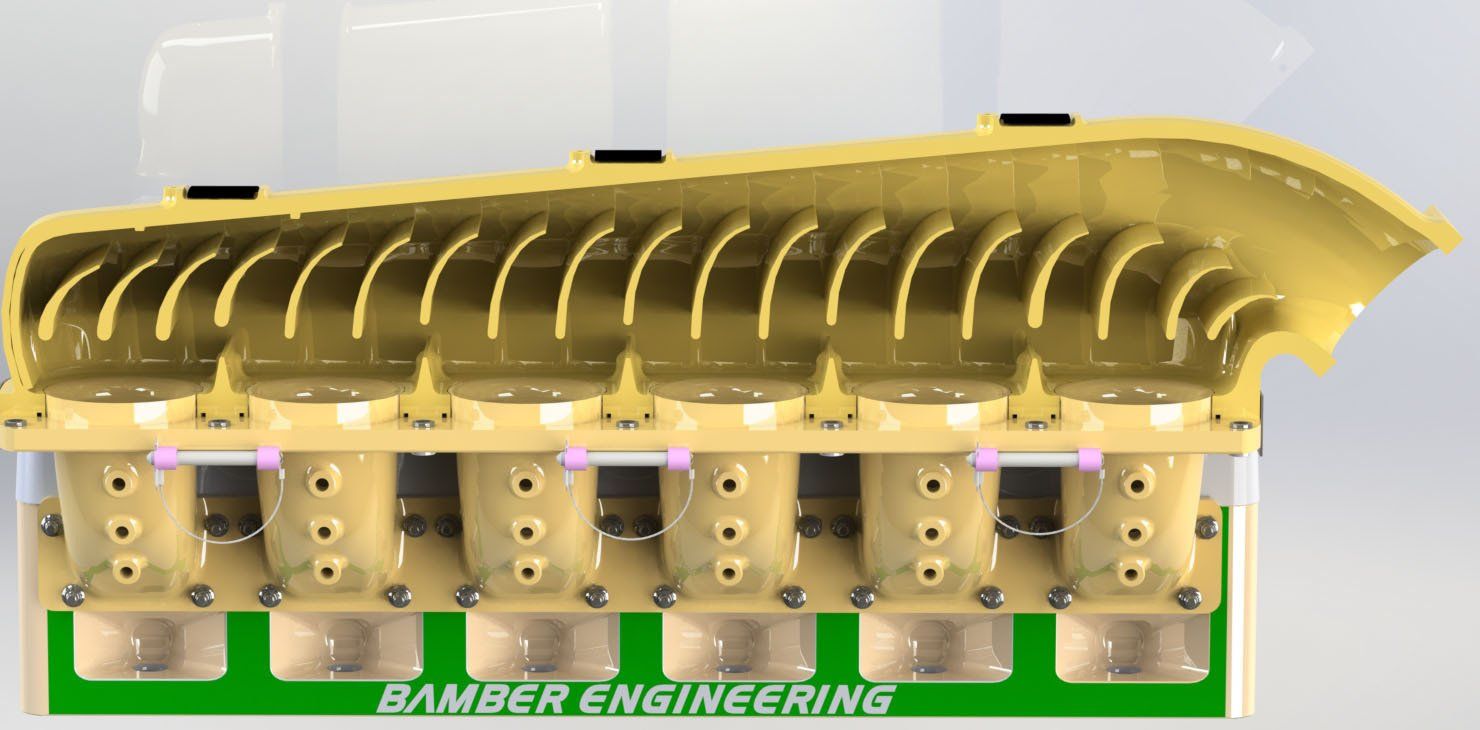

Improved Airflow

Consistent fuel mixtures. Most intake manifold have turbulence which changes with engine speed and boost, which was virtually eliminated with extensive use of Computational Fluid Dynamics (CFD) during design of this manifold.

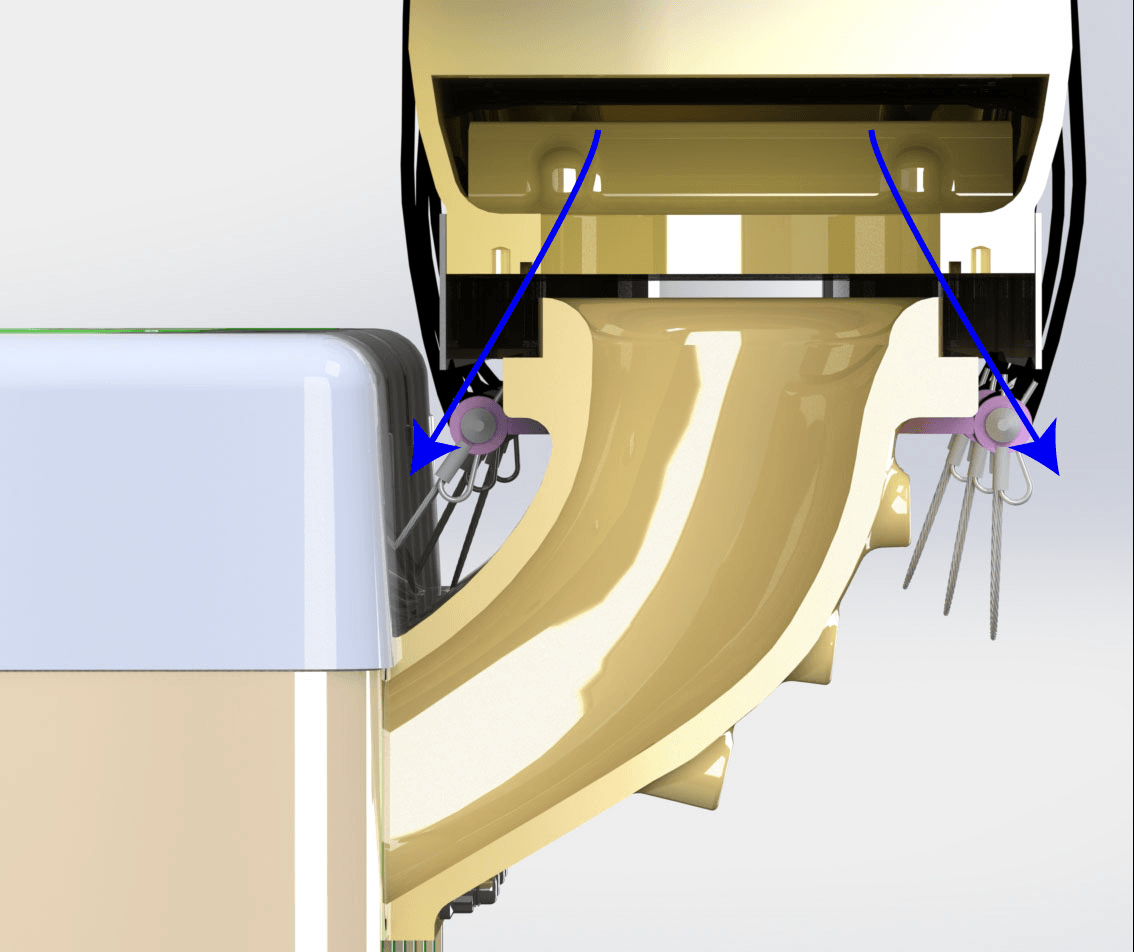

Burst Safety

Safety first. Engineered aluminum studs attach the plenum to the billet runners, providing a "safety fuse" for backfires. The plenum is retained by SFI approved straps, and blast is directed downward.

Improved Fuel Mixing

Fuel nozzles were precisely located to maximize atomization and increase air velocity in each intake runner.

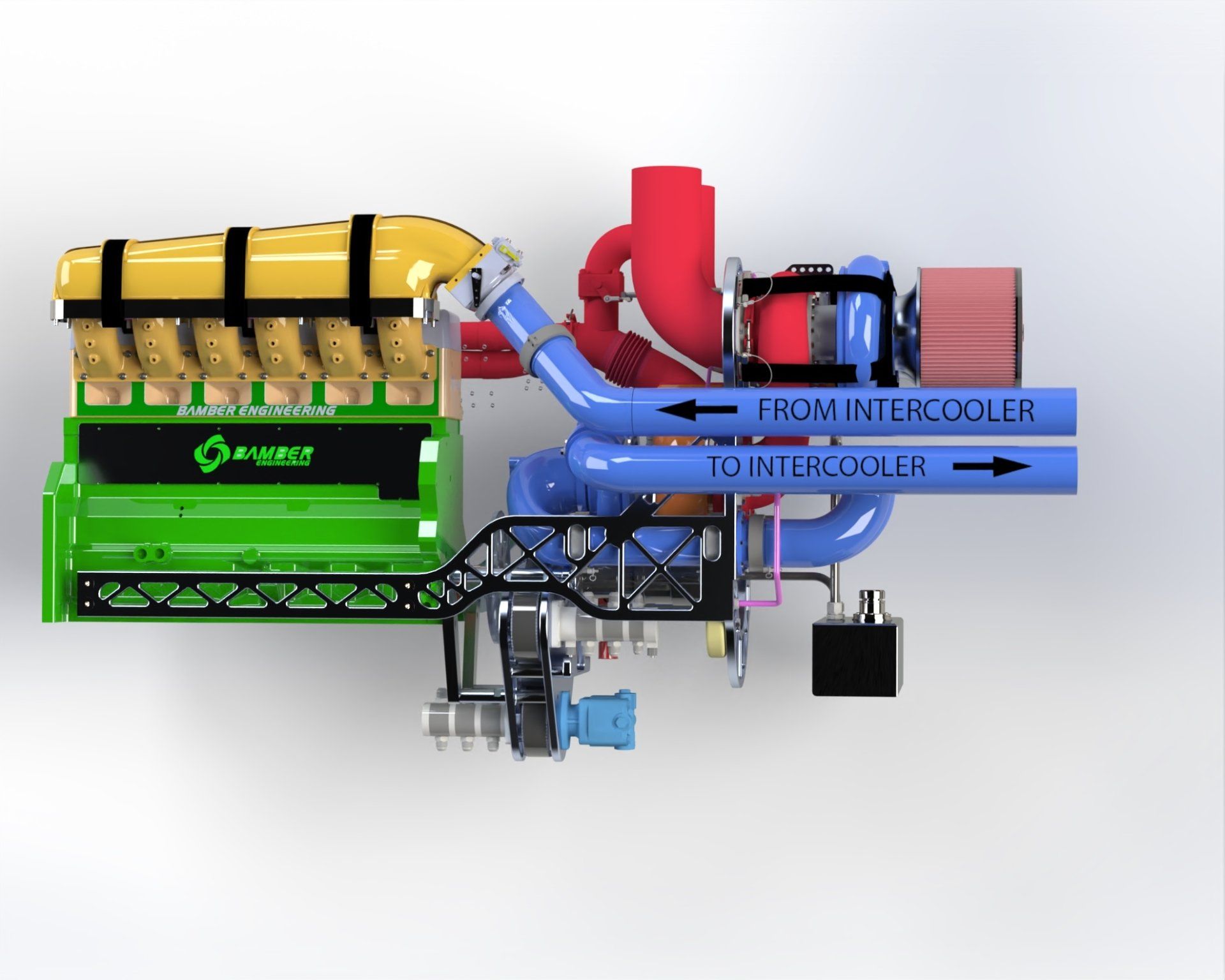

A radical innovation in safety and performance.

Our billet intake manifold improves safety, performance and durability. The blow-off protection minimizes intake damage and the internal airfoils reduce turbulence, providing even fuel distribution. Balanced air and fuel distribution allows all cylinders to provide maximum power contribution, which will show up in competition.

Performance

- Uniform air distribution throughout operating conditions.

- Optimized runner airflow - designed using our airflow expertise (which included flow bench testing and Computation Fluid Design).

- Fuel nozzle placement optimizes atomization and cooling of the incoming air, while driving the air down the runner.

- Three nozzles per runner (in addition to the two per cylinder in the cylinder head) allows for complex fuel systems with a safety circuit.

Burst Safety

- The plenum is attached to the runners with aluminum studs which are designed to fail in the event of a large backfire or explosion, which allows the plenum to lift and vent the excess pressure.

- The venting area is about 8 tmes the venting area of a conventional burst panel.

- In the event of an explosion, SFI approved straps safely restrain the plenum and a stainless steel deflector shield directs the blast downward.

- A flexible element must be present in the intake plumbing to allow the plenum to lift approximately one inch.

Connections

- Each intake runner has three 1/8" NPT connections (at appropriate depth for Waterman HVT nozzles).

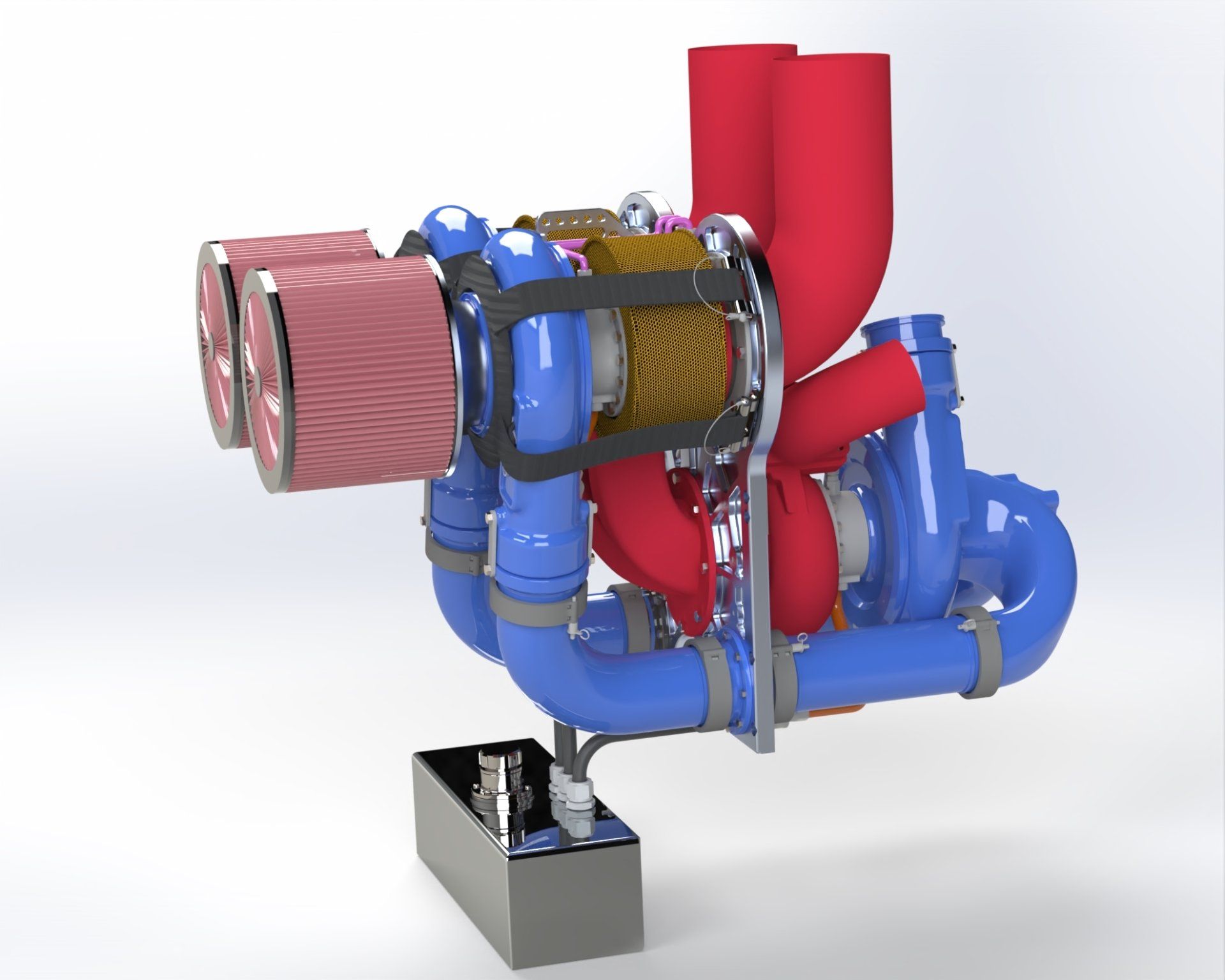

- Inlet flange is configured for a 4" throttle body (compatible with Bamber Engineering Design and Conner Fuel Systems design).

- Four -6 ORB ports are present on the plenum.

- Threaded boss on plenum for throttle linkage attach.

Options

- 4" Throttle body with v-band attach.

- Polished plenum and runners

- Spare aluminum studs

- Waterman HVT nozzle bodies